Exploring the Art of Screen Printing: A Comprehensive Guide to T-Shirt Printing Techniques

When you tip into the world of display printing, you're entering a domain where creativity fulfills craftsmanship. It's not just concerning slapping ink on textile; it's a precise procedure that calls for the right devices and strategies.

The Basics of Screen Printing: Comprehending the Refine

Screen printing, often called serigraphy, is a functional technique that enables you to move designs onto different surface areas. To get begun, you'll first need to create a pattern, which serves as the structure for your style. This entails applying a light-sensitive emulsion to a display and exposing it to light, where your artwork blocks the light from setting the solution.

You then apply ink on top of the display and utilize a squeegee to push the ink with the stencil onto the surface listed below. Understanding these fundamental actions sets the stage for producing dynamic, long-term designs through the art of screen printing.

Necessary Devices and Products for Display Printing

To get started with screen printing, you'll require some vital devices and products. From the best devices to the inks and emulsions that bring your designs to life, each element plays a vital function. Let's explore what you require to do well in this creative procedure.

Display Printing Equipment

While diving into the world of display printing, you'll find that having the ideal tools is crucial for accomplishing high-quality outcomes. Begin with a strong screen printing framework, which holds the mesh that transfers ink onto your fabric. You'll additionally require a squeegee for pressing the ink with the mesh. A good quality direct exposure unit is crucial for developing sharp styles when exposing your screens. Don't fail to remember a washout station for cleansing your screens after printing. Additionally, safety gear like masks and handwear covers is very important for your safety and security. Invest in a reputable heat source, such as a warm press or conveyor dryer, to cure your prints properly. With these tools, you're well on your means to grasping display printing!

Emulsions and inks

Selecting the right inks and emulsions is essential for accomplishing sturdy and dynamic prints. You'll intend to select inks based on your preferred coating and fabric type. t-shirt printing. Plastisol inks are prominent for their simplicity of usage and wonderful opacity, while water-based inks offer a softer feeling and are extra environmentally friendly

Emulsions function as a light-sensitive layer on your displays, essential for creating sharp stencils. Ensure to select a high-quality solution that matches your ink type; some solutions work much better with plastisol, while others are perfect for water-based inks. Appropriate treating is likewise necessary; it ensures the ink sticks well and stands up to washing. By investing in the ideal inks and solutions, you'll boost your display printing game substantially.

Devices for Application

After picking the ideal inks and solutions, the next action is gathering the tools and materials that will aid you apply them effectively. You'll need a durable screen, preferably constructed from aluminum or wood frames, along with a fine mesh for correct ink transfer. A squeegee is necessary for applying pressure and spreading ink uniformly throughout the display. Do not neglect a reputable exposure device to assist you produce crisp stencils. Furthermore, a registration system will certainly assure your styles straighten completely on each tee shirt. You'll likewise desire a washout station for cleansing screens after use (t-shirt printing). Invest in high quality handwear covers and aprons to maintain your workspace clean and shield on your own from ink stains. With these tools, you'll be well-equipped for successful display printing!

Traditional Screen Printing Techniques

Conventional screen printing methods have actually stood the examination of time, showcasing the art and craftsmanship behind this prominent technique. You'll typically begin with a pattern made from a fine mesh material stretched over a frame. This mesh enables ink to travel through while blocking areas you want to stay unprinted. When you have actually prepared your style, you'll apply a light-sensitive solution to the screen and expose it to a light source, hardening the solution where you desire ink to flow.

After cleaning out the unexposed solution, you're entrusted a pattern. You'll after that position your screen on the tee, apply ink on the top, and utilize a squeegee to press the ink through the mesh. This process can be repeated for numerous shades, needing separate displays for every. The result? Vibrant, sturdy styles that display your imagination. Understanding these methods offers you a strong structure for all your display printing ventures.

Modern Innovations in Tee Shirt Printing

Today's t-shirt printing landscape is buzzing with exciting developments that are transforming how you produce layouts. With advancements in electronic printing, green products, and sophisticated personalization modern technologies, you can produce unique, lasting t shirts like never before. Allow's discover these modern techniques and see just how they boost your printing experience.

Digital Printing Developments

As electronic printing technology has actually advanced, it's changed the landscape of T-shirt printing, using you extraordinary precision and imagination. You can currently attain intricate styles with dynamic shades and complex information that were as soon as virtually difficult with conventional approaches. Direct-to-garment (DTG) printing permits you to publish straight onto textile, making it ideal for small runs or customized styles. Plus, the quick turn-around times mean you Get More Information can reply to fads and consumer demands faster than ever. With advancements in ink high quality, you can anticipate toughness and washability that matches screen printing. This innovation not only boosts your style opportunities however additionally opens up doors for special imaginative expressions, allowing your imagination radiate on every Tee shirts you produce.

Eco-Friendly Materials Usage

While checking out modern-day advancements in Tee shirts publishing, you'll discover an expanding focus on environmentally friendly materials that prioritize sustainability without compromising high quality. Additionally, water-based inks are gaining appeal, as they create less damaging drainage contrasted to traditional solvent-based inks. These inks are not only safer for the environment however additionally offer dynamic colors and soft structures on material.

Modification Technologies Development

You now have access to digital printing approaches like Direct-to-Garment (DTG) and Dye-Sublimation, which permit for brilliant shades and complex layouts. These developments make it simple to develop distinctive pieces without the high prices of traditional screen printing. Additionally, online layout systems encourage you to picture your ideas before printing.

Choosing the Right Ink for Your Styles

Just how do you select the best ink for your display printing layouts? have a peek here If you're printing on synthetic products, plastisol inks provide durability and lively colors.

Next, think about the coating you desire. Matte inks offer a subtle look, while glossy inks can add a striking shine. If you're going for eco-friendliness, select soy-based or water-based inks, which are much better for the atmosphere.

Do not neglect about shade mixing; some inks can be mixed to develop one-of-a-kind shades. Examine your inks on example textiles to confirm compatibility and appearance before beginning your primary project. Eventually, the right ink can make a considerable difference in the quality and long life of your designs, so pick wisely!

Tips for Creating Stunning T-Shirt Styles

Creating spectacular tee shirt styles begins with a clear idea that resonates with your target market. Keep in mind, simpleness frequently functions ideal; chaotic designs can confuse visitors.

Incorporate typography that shows the individuality of your brand name-- pick fonts that are readable yet trendy, and mix them sensibly. Take notice of placement; the design needs to flow normally with the tee shirt's form.

Experiment with different designs, such as classic or modern, to find what fits ideal. Don't shy away from making use of negative room properly; it can develop a striking visual impact.

Finally, get comments! Share your designs with pals or potential consumers to determine their responses (t-shirt printing). Their insights can lead you in fine-tuning your work, ensuring your last style is not only sensational however additionally market-ready

Repairing Common Display Printing Obstacles

When you run into obstacles in screen printing, recognizing the origin can make all the distinction. Examine your screen for appropriate stress and validate your solution is fully healed if you notice incomplete prints. For smudging or fuzzy photos, it could be as a result of inappropriate ink thickness or inadequate treating time; adjust your ink or remedy settings appropriately.

If you're dealing with shade inequalities, confirm your ink blending ratios and validate your displays are complimentary and clean of deposit.

Last but not least, if you're experiencing lifting or peeling, take into consideration the kind of material you're using and the heat used throughout treating; various products call for particular inks and temperature levels. By addressing these common concerns systematically, you'll improve your outcomes and boost your confidence in display printing. Maintain exploring, and do not be reluctant to reach out to fellow printers for tips and advice.

Frequently Asked Concerns

Can I Evaluate Print on Fabric Besides Tee Shirts?

Definitely, you can screen print on different fabrics besides t-shirts! Take into consideration items like shopping bag, hoodies, or even table linens. Simply guarantee you're using the ideal ink official site and equipment ideal for the textile type.

Exactly how Do I Clean and Preserve My Screen Printing Tools?

To cleanse and preserve your display printing tools, routinely wash screens with water and suitable cleaners, check mops for damage, and store whatever in a completely dry, dust-free setting to prolong its life expectancy and assure top quality prints.

What Is the Typical Cost of Beginning a Screen Printing Organization?

Starting a screen printing business typically sets you back between $2,000 and $10,000. You'll need devices, products, and a workspace. It's vital to budget plan sensibly and strategy for extra expenditures as your company grows.

Is Display Printing Eco Friendly?

If you choose eco-conscious inks and sustainable products,Display printing can be environmentally pleasant. By adopting ideal methods and minimizing waste, you can minimize your effect while creating vibrant, high-quality prints that interest conscious consumers.

Just How Can I Advertise My Custom-made Tee Shirt Designs Properly?

To advertise your custom t-shirt styles successfully, leverage social networks systems, collaborate with influencers, run targeted advertisements, and involve your target market with free gifts or competitions. Consistent branding and top quality visuals will draw in even more consumers.

Discovering the Art of Display Printing: A Comprehensive Overview to T-Shirt Printing Strategies

Beginning with a strong display printing frame, which holds the mesh that moves ink onto your textile. By spending in the appropriate inks and solutions, you'll boost your screen printing video game considerably.

With advancements in ink quality, you can anticipate toughness and washability that matches screen printing.Just how do you pick the best ink for your display printing styles?

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Shane West Then & Now!

Shane West Then & Now! Bill Murray Then & Now!

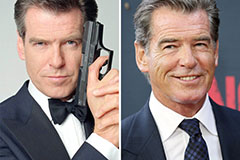

Bill Murray Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!